Extract from History of Finmere, published 1887

Extract from History of Finmere, published 1887

| £. s. d. | |

| Mr. Purbeck Temple | 2 0 0 |

| Mr. James | 1 0 0 |

| Mr. Ells Rector | 2 0 0 |

| Mr. Painton | 1 10 0 |

| Mr. Chaplin | 0 10 0 |

| Mr. Horne | 0 5 0 |

| Thomas Crow | 0 5 0 |

| Thomas Chappel | 0 5 0 |

| James Robbins | 0 2 0 |

| Henry Tappin | 0 2 0 |

| Nicolas Finch | 0 1 0 |

| Richard Edwards | 0 1 0 |

| Richard Boughton | 0 1 0 |

| Anne Middleton | 0 0 6 |

| William Cheynells | 0 1 0 |

| John Hatton and Beatrice | 0 1 6 |

| Tho Neele | 0 1 0 |

| John Stevens | 0 0 6 |

| Thomas Savage | 0 1 0 |

| William Archer | 0 1 0 |

| George Middleton | 0 1 0 |

| Elizabeth Warre | 0 2 6 |

| Total | 8 12 0 |

| The clock cost | 8 10 0 |

| Given to Mr. Ford's man | 0 2 6 |

Another quotation from the History of Finmere: Another old custom has come down to the present day. On Shrove Tide, or Tuesday, it was usual to ring one of the Church bells to summon the people to the confession of their sins (shrive or shrift, a.s., meaning confession) preparatory to Lent. This, in later times, degenerated into a signal for preparing the pancakes, which were commonly eaten on that day. Taylor, the Water Poet, gives the following curious description of Shrove Tuesday:-

"At whose entrance in the morning all the whole kingdom is inquiet, but at that time the clocke strikes eleven, which, by the help of a knavish sexton, is commonly before nine, then there is a bell rung, cal'd the Pancake-bell, the whereof makes thousands of people distracted, and forgetful of either manners or humanatie; the there is a thing called wheaten floure, which the Cookes do mingle with water, eggs, spice, and other tragicall, magicall enchantments, and then they put it by little and little into a frying pan of boiling suet, when it makes a confused dismall hissing (like the Lernean snakes in the reeds of Acheron, Styx or Phlegeton), until at last by the skill of the Cooke it is transformed into the form of a Flip-Jack cal'd a Pancake, which ominous incantation the ignorant people doe devoure very greedily"

It was the daye whereon both rich and poore

Are chiefly feasted with the selfsame dish,

When every paunch, till it can hold no more,

Is fritter-filled, as well as heart can wish;

And every man and maiden doe take their turne

And toss their pancakes up for fear they burne,

And all the kitchen doth with laughter sound

To see the pancakes fall upon the ground.

(curious poem from Pasquil's Palinodia, 1634)

The Curfew-bell has also continued. At the beginning of the last century (18th) it was rung only from Michaelmas to Lady-day.

It is still rung from October 11th to April 5th

The balance of 2s 6p given to Mr Ford's man referred to above may

mean that the clock was made by John Ford, Freeman of Oxford in 1697.

An inventory of goods belonging to Finmere Church in 1733 includes 3 bells and 1 clock.

In 1731, Thomas Chanels was paid 5s a year for looking after the clock from 1710 to 1761.

John ford, Oxford? Aylesbury? (16??-1725) Clock and watch maker. Son of William Ford, Cleric, late of Heyford, Oxfordshire. Apprenticed to John Knibb, Clockmaker of Oxford on 28.4.1682 for 8 years. Freedom of Oxford on 10.7.1691. According to the Window Tax of 1696 a John Ford had a large house in High Street, Oxford. In April 1708 he was loaned £25 by the City Council. Probably moved to Aylesbury where he was recorded insolvent in 1725 .....

Installed the clock in Finmere Church in 1697.

Extracts from Antiquarian Horology Summer 1979 - TWO TURRET CLOCKS WITH SPRING REMONTOIRES by D.F. Nettell

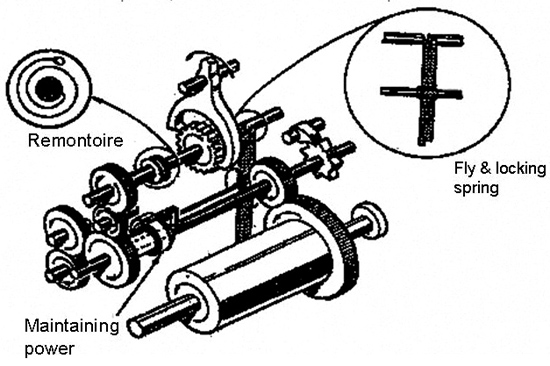

In his classic book on turret clocks, Lord Grimthorpe described a spring remontoire and claimed it as his own invention . Although rarely seen, two examples have come to light from the villages of Finmere and Dadford near Buckingham. Evidently both are by the same hand, a retired medical man turned horologist, one Dr. Clarke.Finmere Church Clock

The clock is of the bird cage pattern and is rather lightly built. It has very attractive brass filials on the corner posts and an upward curving bar between the two pivot bars carrying the setting dial.A modification made at the time of the moving of the clock from the tower to the alcove at the base of the tower was the provision of external barrels, a feature not unusual with Victorian "improvers", to increase the going time. At Finmere, shafts engaging the winding squares pivot in plummer blocks supported in a cast frame outside the alcove. These external barrels clearly to be seen. These shafts, one for the going train and one for the striking train each carry a pinion. The pinions engage with wheels connected with cast iron barrels. On the going train, the connection between the gear wheel and the barrel is through a ratchet wheel and clicks. The barrel carries a winding square for winding the comparative light weight. The ratio of about 6:1 between the wheel and pinion should extend the going period for about a week

(note by E. Harkness - this is not possible since the winding lines of the going system cross over the lines of the striking system ! - only about 4-5 days is possible).

Returning to the going train, the next item of interest is a version of Harrison's maintaining power. The great wheel drives a pinion on the second arbor in the usual way. However, the wheel at the other end floats freely on the arbor. A spiral spring, whose centre is fastened to the arbor, has its outer end secured to an axially projecting pin on the floating wheel. The spring therefore transmits the torque from the barrel to the floating wheel and winds up in doing so until the spring torque balances the barrel torque. On the second arbor also, there is a ratchet wheel restrained by clicks. The ratchet wheel maintains the torque to the spring while winding is in progress and torque taken off the barrel. The floating wheel drives the spring remontoire through a train of small wheels and also the remontoire letting off mechanism through a second pinion.

The remontoire comprises a disc floating on the 'scape arbor powered through the train from the second wheel. The disc has an axially projecting pin which secures the outer end of a spiral spring. The inner end of the spring is hooked on to a boss fastened to the 'scape arbor. If the outer end of the spring is kept in tension, therefore the inner end will propel the 'scape wheel. The hooked boss also has a flange to prevent the spring from telescoping along the arbor. The second wheel also drives a pinion on an arbor containing the unlocking device. This comprises a fly having a projecting flat spring at the extremity of each vane. The springs are axially displaced by about one inch. The springs bear against the 'scape wheel arbor. However, there are two slots cut in the arbor through which the springs can pass. The slots are set at 180? to one another so that once one slot has allowed the fly to escape, the fly rotates and locks on the 'scape arbor until released by the other slot appearing 30 seconds later. As the fly is connected to the remontoire through the train, the mechanism rewinds the remontoire every 30 seconds. The two slots in the 'scape wheel arbor differ rather from Grimthorpe's description. He used axially disposed stops, one long, and narrow, the other short and wide which engaged and passed through corresponding, slots in the face of the arbor. Fig.1 shows the main features of the train diagrammatically.The 'scape wheel itself is of the dead beat type. It is much later than the date of 1697 ascribed to the clock but Dr. Clarke could have fitted it when he made the other alterations.

The great wheel drives an hour arbor mounted in the curved horizontal between the pivot bars. This might appear a rather strange arrangement as the spring in the maintaining power could have an affect on the movement of the hand. As it is, the minute hand steps slowly in half minute steps as the remontoire releases.A pair of bevels on the hour arbor drive the leading off rod and these are secured to the wall by intermediate bearings. Another interesting feature of the clock is the striking system. Most clocks have lifting pins on the great wheel and raise the bell hammer through wires. The Finmere clock drives a leading off rod through a pair of bevels. The striking, rod runs up the wall parallel to the dial leading off work; and disappears into the tower. There, under the floorboards of the belfry, the rod ends in a cam mounted in a horizontal plane.

The cam follower is connected by wires and bell cranks to strike on the largest of the three bells. The cam makes one revolution for each blow on the bell. Fortunately, the clock is in working order although a repair was needed recently to the remontoire spring. It is said to keep excellent time and thus justify Dr. Clark's efforts.Beeson devotes a fair amount of space to this clock '. He refers to the churchwardens' accounts and the " Rectors Book". These name many of the clock makers who looked after the clock in the 18th and 19th centuries. In the biographical section, he includes an entry on Dr. James Clark. There is, however, no description of the clock and its unusual features. It seems likely, therefore, that Beeson did not inspect the clock personally and relied solely on the records written by persons not having, an appreciation of the finer points of horology. He mentions also that the dial is a wooden hexagon, painted white with slender black hands. At the time of writing, the dial is square, (summer 1979), possibly metal, with a wooden surround, painted blue with yellow hands and chapters. Beeson does not refer to the Finmere clock in "English Church Clocks".

The Clock from Boycott ManorA mile or two away from Finmere at Boycott Manor, there was once another clock having some of these unusual features. It includes a similar remontoire. It also had a curious escapement based to some extent on the slotted locking and release mechanism of the remontoire.

The 'scape wheel has six arms not unlike a double three-legged gravity escapement. The power of the train (acting through the remontoire) propels the arm against an arbor rocked by the pendulum. This arbor has a slot in it and when the slot rocks to the correct position, it releases the arm. The alternate arms of the six have the tips turned over in a radial direction. These engage with the edge of the slot in the rocking arbor. On the return stroke of the rocking arbor, a slot cut axially in the arbor appears and allows the bent over tip to pass. The arm thus escapes until the next arm comes up against the arbor, the escaping slot in which is tilted out of the escape position.

Notes gathered by Mr. P. Willison:

Finmere Church ClockThe clock was cleaned in 1738 by a Mr Bradford and by him on 8 other occasions at 5s. a time until 1775. This man was either Thomas or James Bradford, clockmakers of Buckingham. The clock winder was paid 6s. a year from 1761 to 1795 and at 10s. a year to 1827. In 1776 a Mr Packer was engaged at 5s. for what is described as "Doing ye Clock" and this arrangement continued until 1825 with the wage raised to 10s a year in 1810. William Packer was a clockmaker in Buckingham at the end of the 18th century and John Packer has his workshop in Tingewick, the next village to Finmere, in the 19th century. He made the clock in Newton Purcell church (q.v.).

In 1827 William Stanton, clockmaker of Buckingham, was responsible cleaning and repairing the clock until 1844, when Willam Bayliss of Finmere replaced him and remained in charge of the clock for the next 40 years with Gabriel Friday as winder. During the period of 130 years from 1731 clock lines and wire were bought on 16 occasions and "2 new wheels" in 1831; as the latter only cost 5s.6d. they were probably pulleys.The dial was repainted in 1783 and 1808 by Gunn and 1831 by Tappin. It is a wooden hexagon painted white with slender black hands.

RECENT HISTORYLog kept by Mr Philip Willison

In 1977 the clock was examined and repaired by Mr. W. Watts of Buckingham at a cost of £38:00.In September 1978 the spring on the remontoire movement had come adrift from spindle and could not be replaced. In January 1979, the clock was examined by Mr D.F. Nettell, Diocesan Clock Advisor. Pin provided by DFN fitted by Philip Willison, spring tension adjusted and clock resumed functioning. Lubricated overall, including mechanism in belfry.

July 1979 - New remontoire spring fitted; mechanism in belfry cleaned and oiled; fly springs eased to prevent fouling of the release slots - both vanes seem to have fatigue cracks leading to possible distortion - timing adjusted.April/May 1982 - Clock ceased working due to breakage of one vane of the fly, at the position of the cracks noted in 1979. The fly was repaired by rivetting a plate across the fracture, by David Jones of Station House, Newton Purcell. It was re-balanced and fitted back in the clock. Difficulty was experienced in getting the remontoire mechanism to function regularly and adjustments were made as follows:

1. New remontoire spring fitted

2. Both flyspring (on repaired side) and slot on escapement arbor eased to avoid occasional fouling.

3. Relative position of wheels in gear train of remontoire altered as the centre idling wheel seemed to be bottoming in one position which provided enough friction to stop the clock at approximately 20 minute intervals. It is therefore important that if the fly is removed for repair, the gear train is kept in the same relative position as before stripping down.

The clock was lubricated, including the gear train in the belfry. It is difficult to ensure adequate lubrication of the hour hand and minute hand rod, which pass through the tower masonry.

Clock was lubricated in June 1983, August 1984, September 1986, December 1987In 1994, the clock face was renewed in its original hexagon shape by Smiths of Derby. At the same time the striking mechanism was straightened and the steel cables renewed.

In 1996, Peter Meacham, Clockmaker of Milton-under-Wychwood dismantled and fully overhauled the clock mechanism. With minor adjustments the clock is now fully functional and keeps excellent time.In 2002, it was realised, that the main maintenance requirement is to lubricate the clock going train since rusting occurs over a period of time between the gear wheel and the barrel. This barrel movement is only due to the slow movement, which occurs as the clock operates - it does not move when winding up the weight.

Prepared by Eric Harkness, The Old School, FinmereUpdate - In 2010, for reasons of safety, a decision was made to electrify the winding of the clock weights. The work was consequently undertaken using funds raised by the villagers.